I thought I would throw up a how to thread on making Micarta and working with both Micarta and G10 knife scales

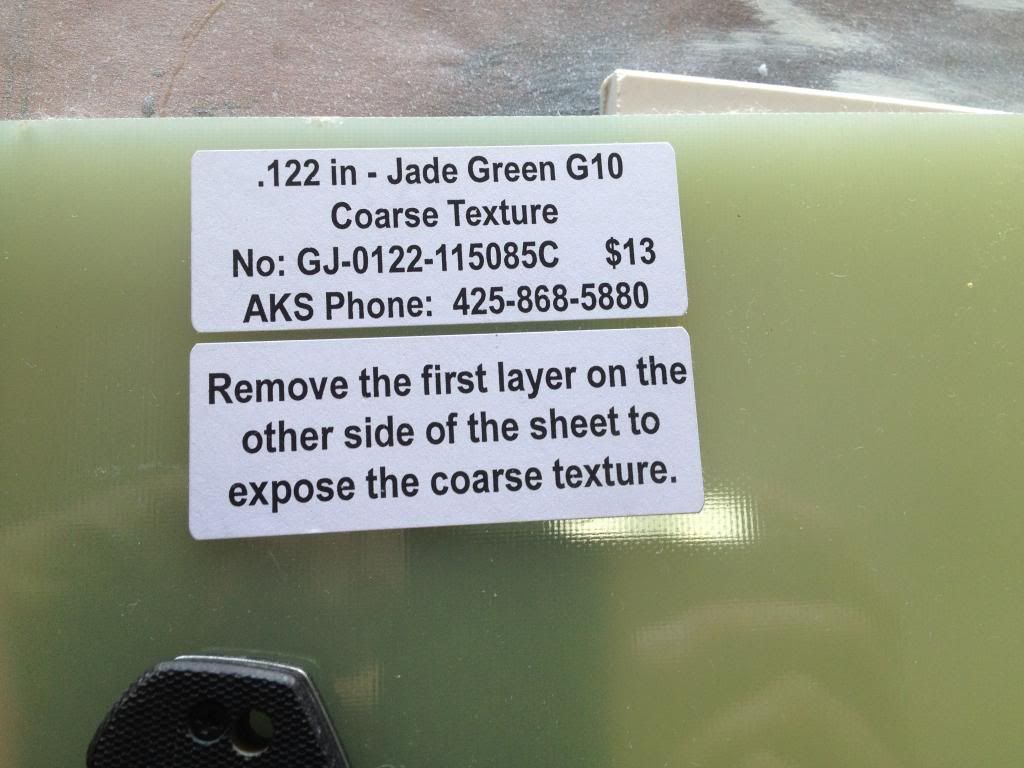

Micarta is essentially "fiberglass" but instead of using actual fiberglass matting of mesh you use an alternative media, and pretty much anything will work. G10 is actually closer to "fiberglass" in that it does use a fiberglass mesh material with different colored resins.

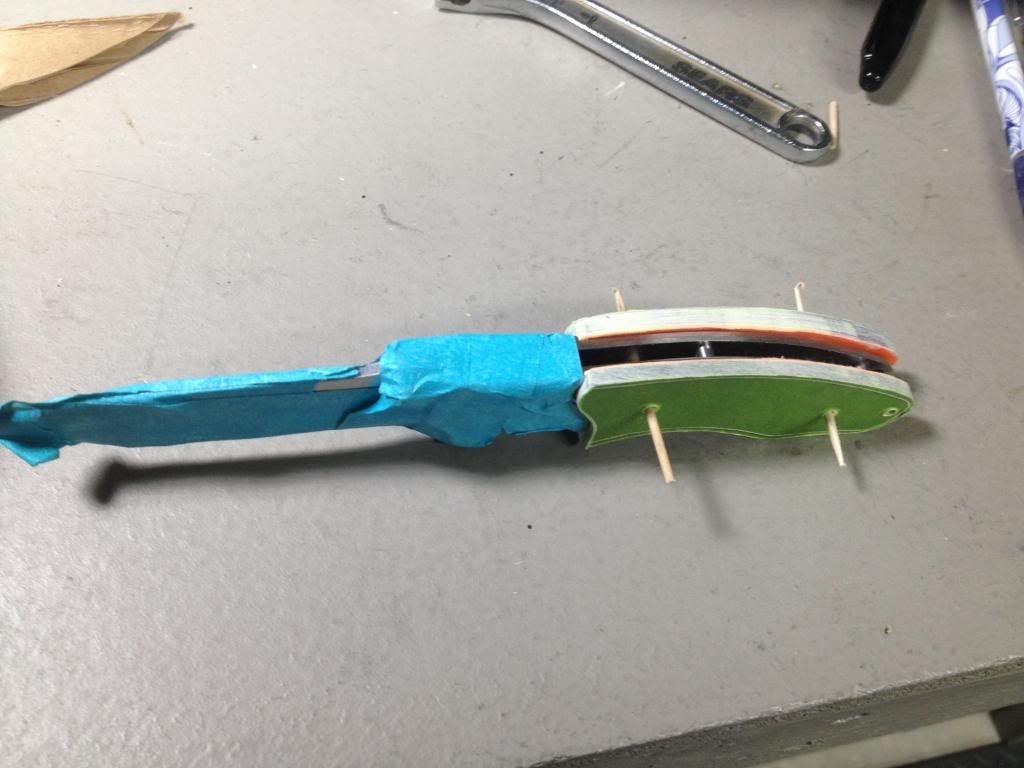

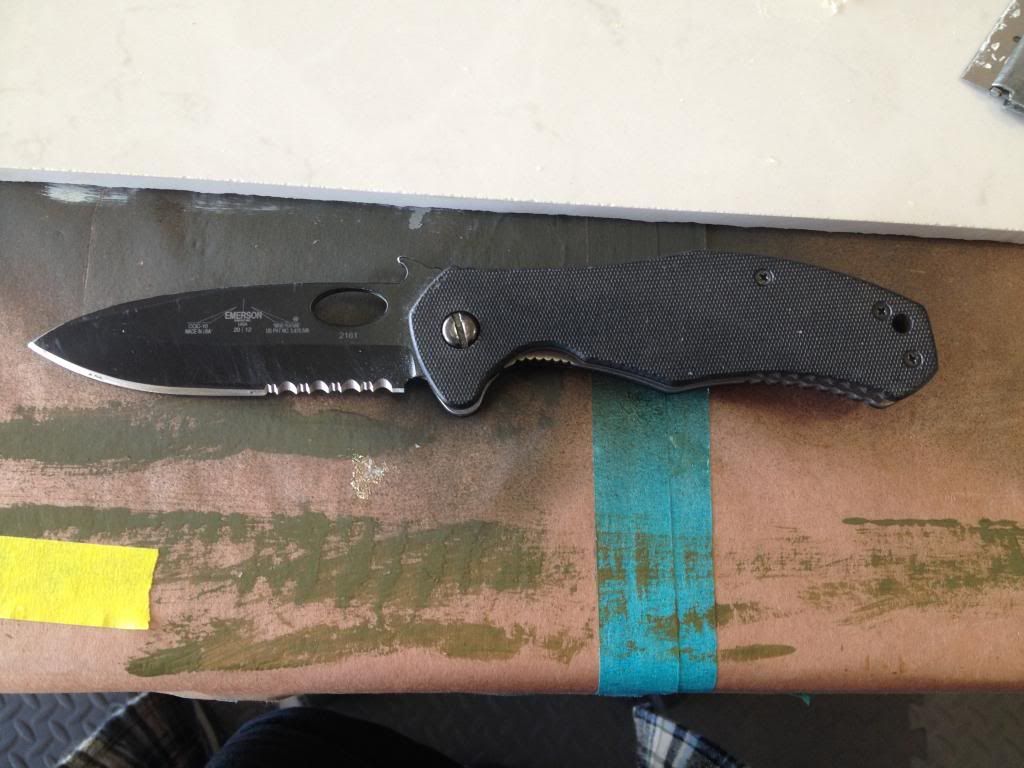

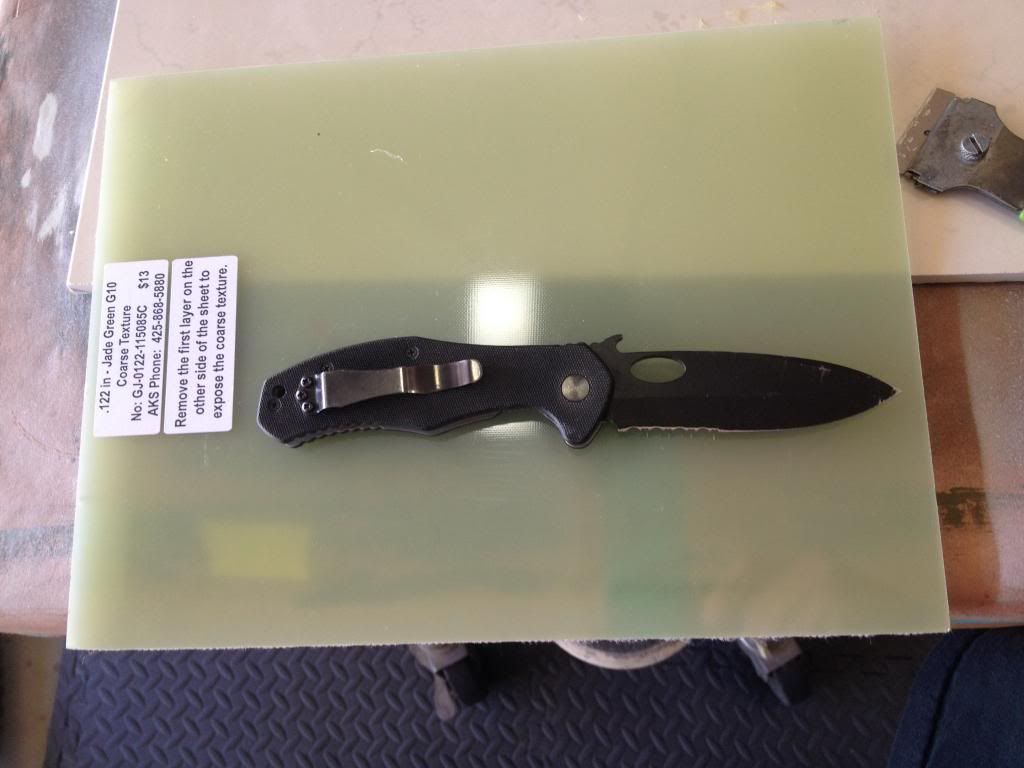

This first one is mine and was just something I wanted to mess around with. I took my daily folder and took the original wood scales off so I could make some new ones for it.

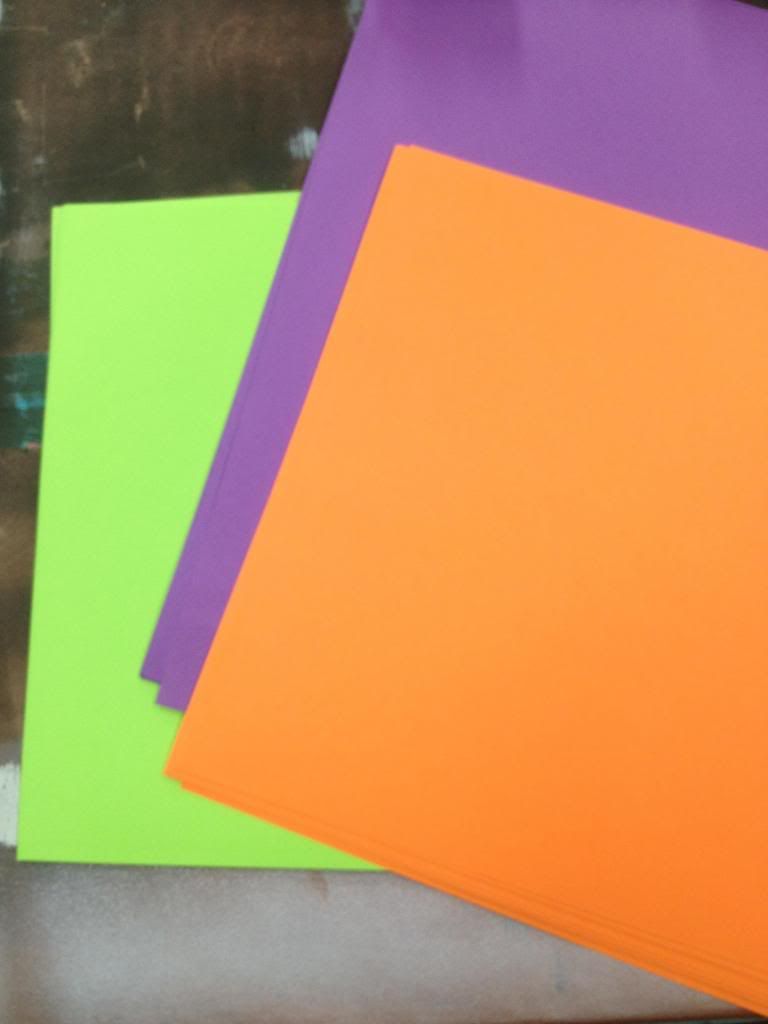

The media I chose for this one was colored construction paper. I wanted something different and I think this hit the mark. I cut 2" strips of the paper.

Regular old Parchment Paper seems to work the best and does not stick to anything!

Work station, you need two flat surfaces which I will talk about more later, and your parchment paper, fiberglass resin a mixing bucket, rubber gloves a mixing cup and some mixing sticks a respirator and VERY GOOD ventilation.

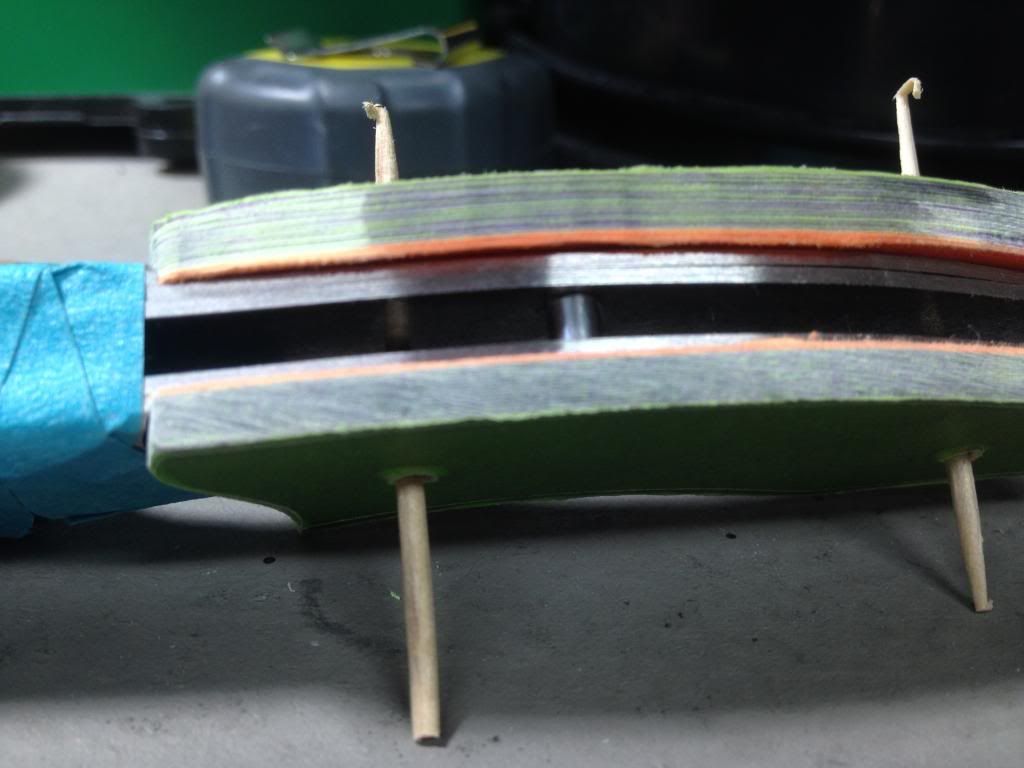

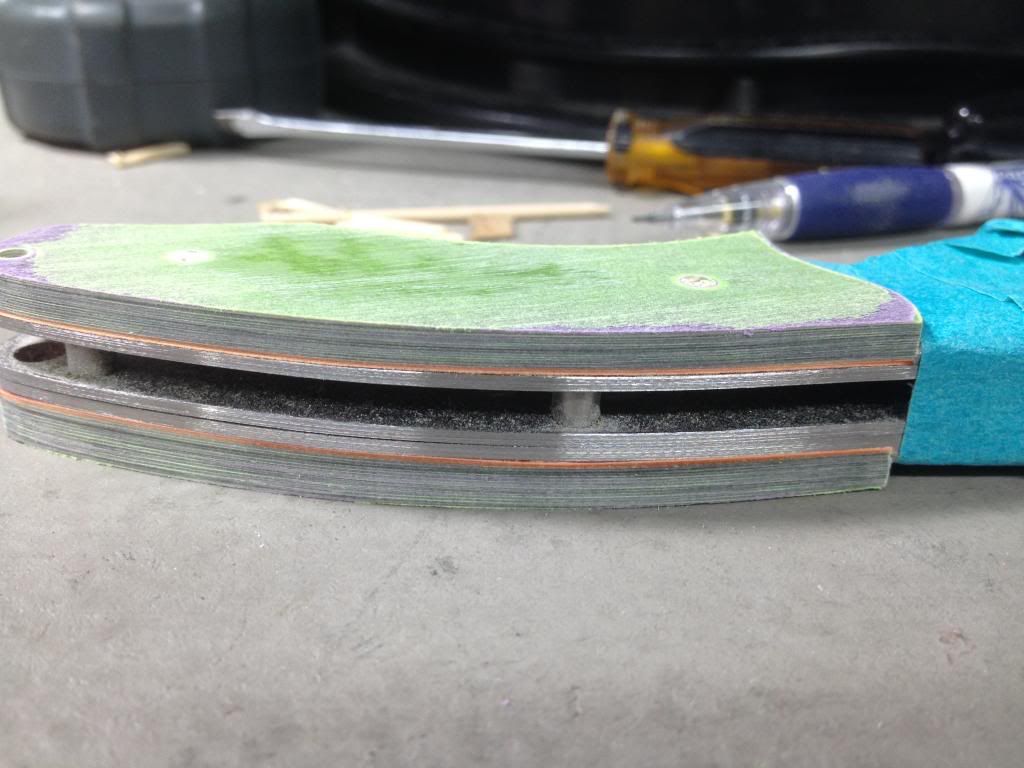

I wasnt able to get a lot of pics during the process as it is very messy and somewhat time sensitive and you have about 10-12 minutes of work time if you mix it per the instructions. Having said that and the fact that I have been working with fiberglass resins for over 20 years I know how to manipulate the resin to kick as slow or as fast as you like just by adjusting your amount of catalyst and heat. When making it I coat both sides of the first piece of material with resin, then lay the next piece on top of that and coat the top of each piece of media as I layer it up.

As soon as you have it wrapped up tight you need to clamp it all up, and clamp it TIGHT AND EVEN. If you clamp it uneven you will end up with an uneven end product.

It dries in about two hours if mixed per the product instructions but I let it sit over night.

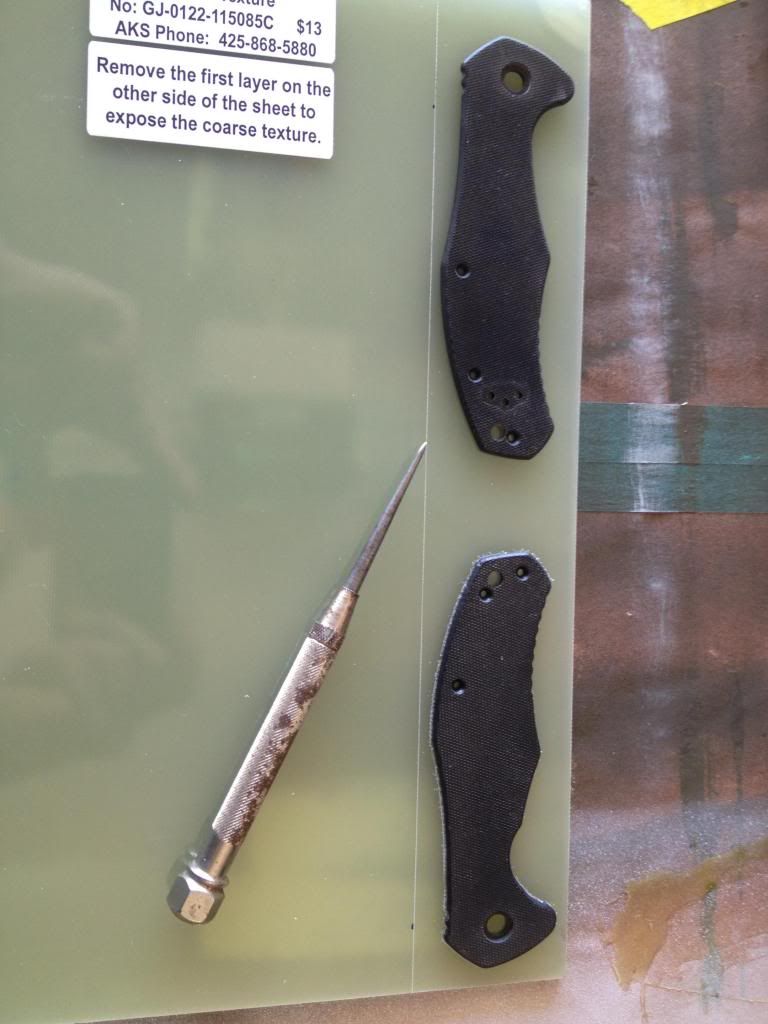

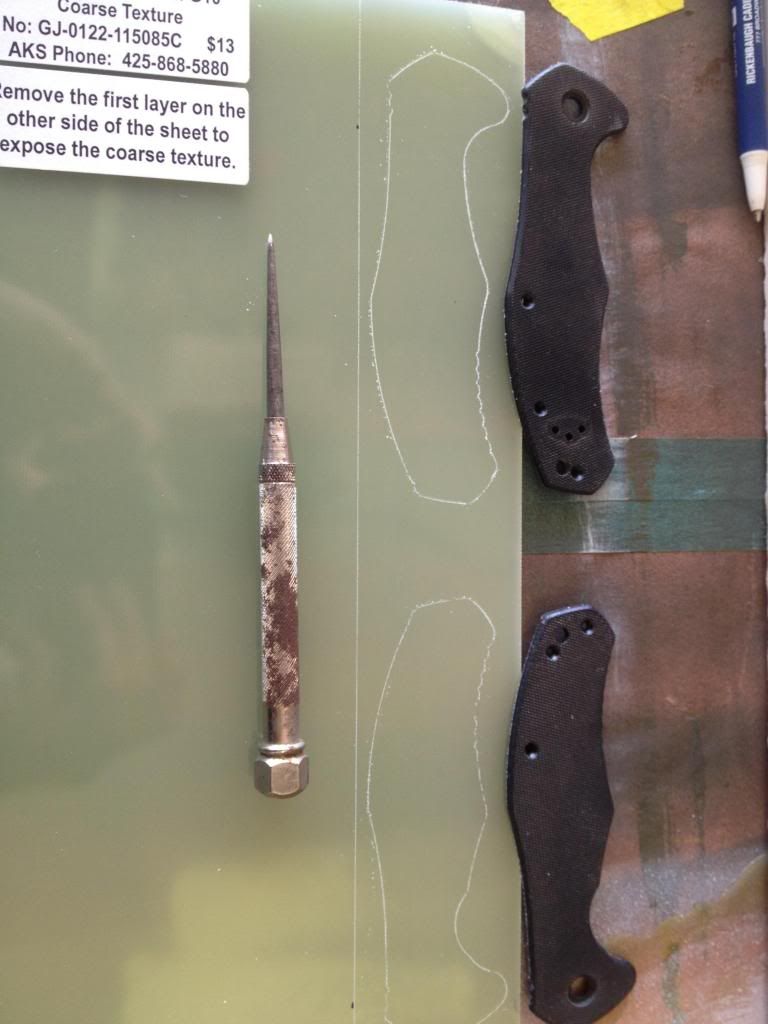

Start by tracing out your old scales (if you are copying old ones) or draw the shape of your end desire on the material. I then take an awl (or center punch) and scribe the lines that I want to follow. Scribing the lines almost ensures you dont lose your pencil lines when working up your final shapes.

I built myself a little "sanding box'' so I could try and containg as much of the dust as possible. Be sure to wear a respirator or at minimum a dust mask and eye protection.

Ok, then you need to start out by getting your initial rough cut done on the band saw.

Then mark your holes so you can drill them out. I take the old scales and clamp them to the new media and mark the center of the holes with a center punch.

Reply With Quote

Reply With Quote