It started with a R700 that wouldn't give up the barrel. No problem, just give a tiny bit of the heat, and off it comes!

It's a little dirty, so lets just clean it right out.

The lower lug had good contact, but the upper lug had (guess-timating) less than 20% engagement area. Hand lapping will help with that. The receiver was less than .0005" off from concentric, so no need to thrown it in a lathe.

A little bit of friction in the bolt was causing a binding in the cocking action. A couple turns with a strop, and all is well.

Time for the barrel install.

Bigger recoil lug on the right, because why not.

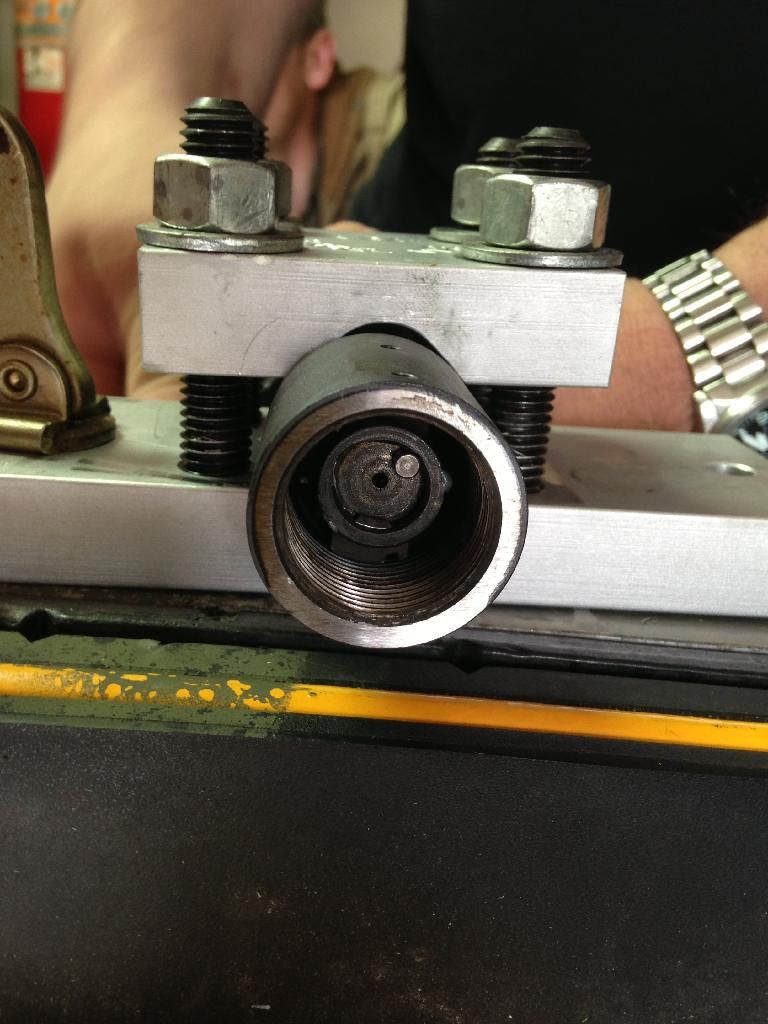

Close up of the barrel nut system.

It's not very short.

The gun, as it sits...

Reply With Quote

Reply With Quote