Now I have to start working on the handle my lease favorite part of knife making.

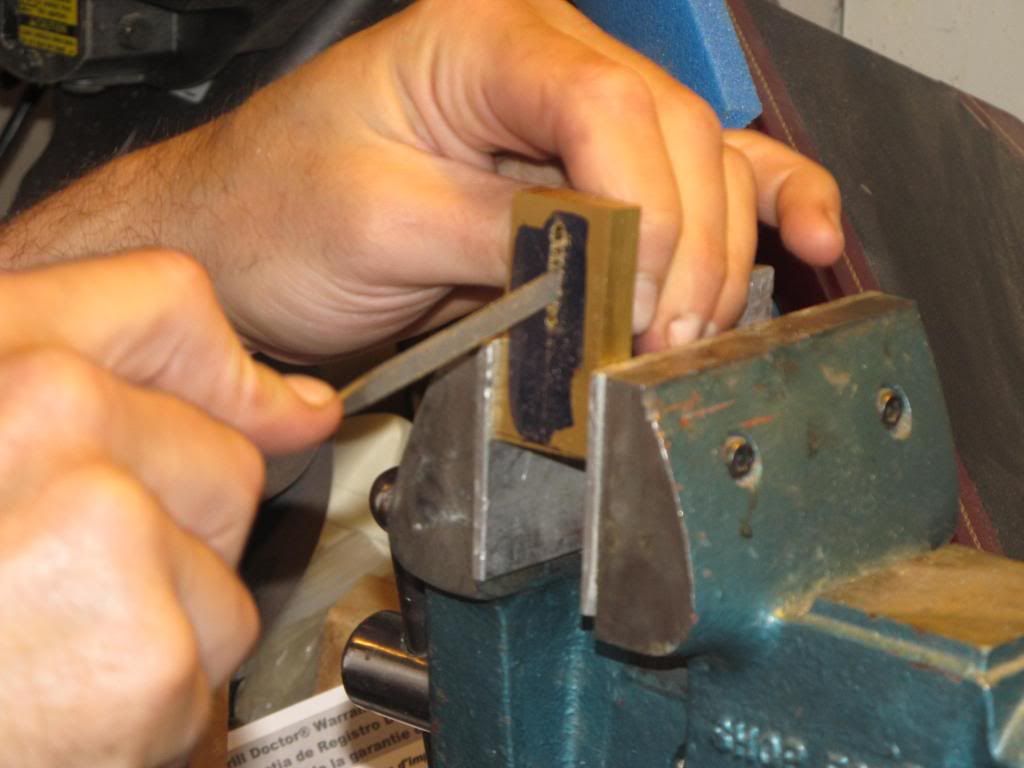

I start by drilling a series of holes in a piece of brass that are smaller then the with of the ricasso then use a file to open up the area until it takes a little hammering to get the guard on the knife.

I do as much shaping of the guard as I can before gluing it in place. There is a lot of putting it on with the elk antler handle to make sure that everything is flat and lines up the way I want it. I use JB weld to seal the area around the guard to make sure that no blood or moisture get between the guard and the blade which would lead to rust if it wasn't sealed.

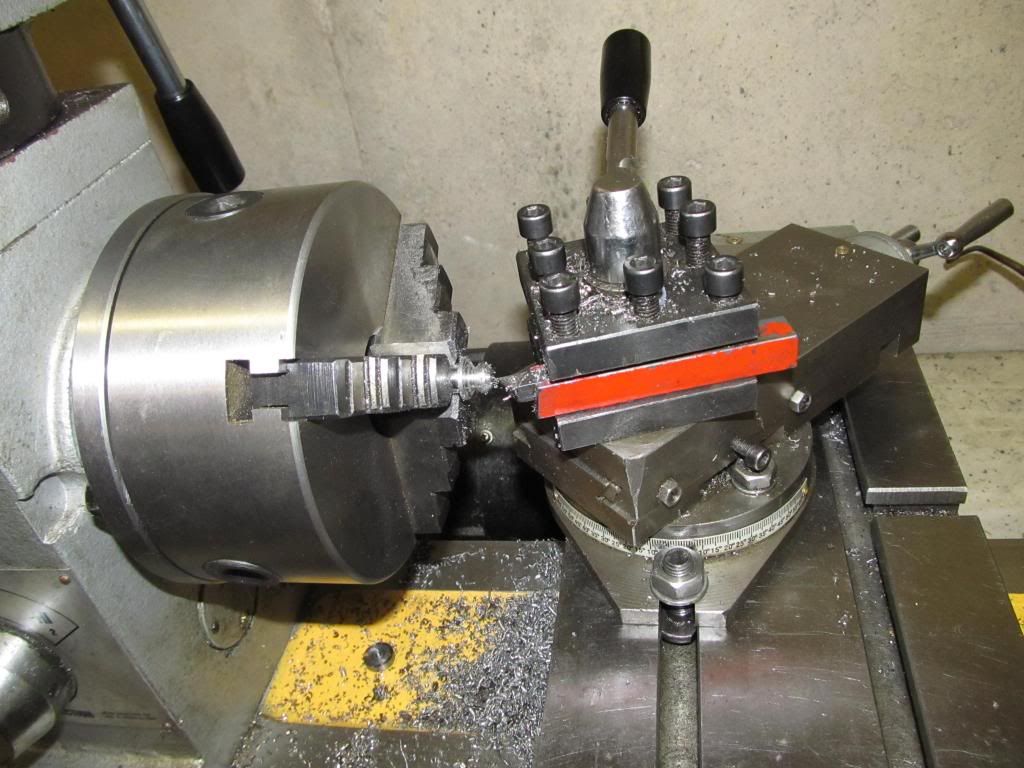

Then a thread the tang of the knife and then use a piece of damascus to make a pommel that will fit though a piece of brass and screw on the the tang holding everything together.

Here is a crappy pic of the finished pommel before it is sanded to 1000gr, etched, and blued.

You have to remove all to the pith in the antler otherwise it will deteriorate over time and crumble then you have a loose handle, so I use a drill and dremel tool to clean out the antler then use slow cure epoxy to fill in the gap between the tang and the elk antler, cap it with the brass piece put loctite on the pommel and screw it down tight. Then it's a lot of hand sanding to blend the guard, antler handle, and brass cap together.

Then it's on to making the sheath but thats another post.

I hope this gives you an idea about what it takes to make a custom knife, for me start to finish is 6-8weeks for a knife like this. If I'm doing a stock removal or forging one from bar stock you are looking at about 4 weeks give or take.

Reply With Quote

Reply With Quote